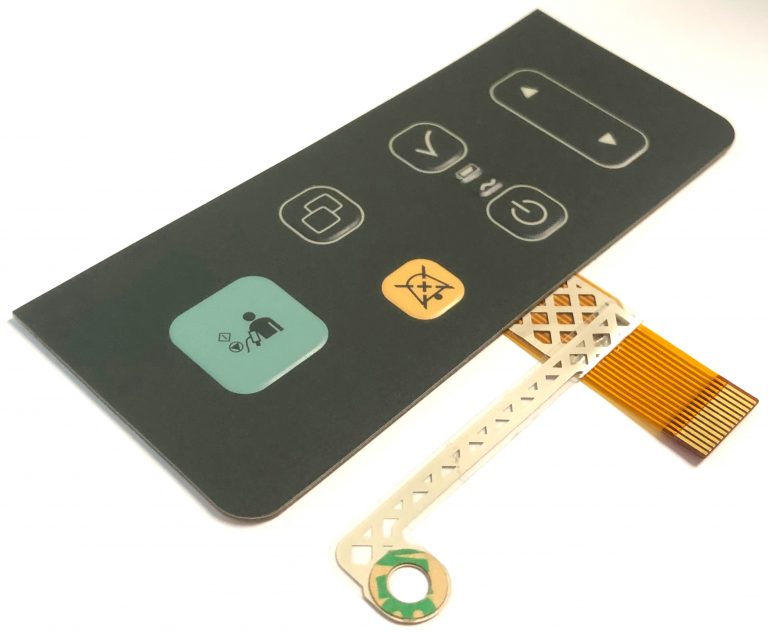

Discover the Versatile Use Membrane Switch in Modern Electronic Devices

In the world of modern-day electronic devices, the application of membrane layer switches is incredibly extensive, spanning from streamlined customer gadgets to vital medical gadgets. These thin, adaptable interfaces not just simplify device operation with their responsive responsiveness yet likewise considerably enhance resilience by standing up to ecological dangers like wetness and dirt. As industries remain to develop, the assimilation of membrane buttons in equipment layout is essential, encouraging not only to fulfill however surpass the extensive demands of both capability and visual allure. Discover extra about how these elements are forming the future of innovation.

Exploring the Duty of Membrane Switches Over in Customer Electronic Devices

Why are membrane layer switches so common in consumer electronic devices? The response hinges on their special combination of flexibility, reliability, and cost. Membrane layer switches are cost-efficient to manufacture, making them an eye-catching choice for high-volume production regular in consumer electronic devices. Their building and construction, including a thin, versatile layer that can easily be incorporated right into different gadgets, enables streamlined, portable item styles.

Moreover, these switches are recognized for their longevity and reduced maintenance. They are immune to dirt, moisture, and dust, which improves the longevity of the electronic gadgets they are made use of in. This reliability is critical in daily consumer products that undertake constant use. Additionally, their versatility in layout allows customization in visual appeals and functionality, satisfying the particular demands of different digital devices. From microwave stoves to remote controls, membrane layer buttons provide a functional, straightforward interface that supports the vibrant nature of customer electronics.

Membrane Layer Switches Over in Medical Instruments: Enhancing Customer Interfaces

Membrane buttons likewise play a considerable duty in the world of medical gadgets, where they improve interface with their unique benefits. These buttons are particularly valued for their reliability and convenience of sanitation, crucial in medical care atmospheres where sanitation is paramount. The smooth, sealed surface area of membrane layer switches allows for easy sanitation, decreasing the risk of contamination and spread of virus. Furthermore, their style adaptability accommodates the visual and ergonomic requirements of medical tools, making tools extra instinctive and accessible for medical care specialists.

Membrane view layer buttons additionally add to the longevity of medical tools. Their resistance to contaminants and web liquids makes certain that essential devices continues to be functional in different scientific settings, consisting of surgical procedures where exposure to liquids prevails. This toughness, combined with tactile responses and low-profile layout, makes membrane changes an indispensable component in boosting the performance and security of medical tool user interfaces.

The Influence of Membrane Layer Activates Industrial Equipment Layout

In the world of industrial devices style, the consolidation of membrane layer switches has noted a substantial advancement. These buttons have actually changed exactly how makers approach interface functionalities, using a mix of longevity and flexibility that is essential in harsh settings. The slim profile of membrane changes permits more compact equipment designs, while their resistance to water, dirt, and chemical pollutants makes them ideal for commercial setups. This versatility has actually assisted in the development of equipment that is not just much more durable however likewise simpler to maintain and tidy, therefore minimizing downtime and functional expenses.

Furthermore, the customizability of membrane layer changes makes it possible for designers to integrate certain responsive responses and visual overlays that improve the individual experience and boost efficiency. This assimilation sustains operators in accomplishing precision control over intricate machinery. The general click for info influence is a considerable enhancement in the capability, integrity, and user-friendliness of commercial devices, aligning with the increasing demands for technological advancement and operational efficiency in modern-day sectors.

Conclusion

Membrane layer switches have actually transformed contemporary electronic devices, supplying smooth, durable, and personalized user interfaces across various markets. This modern technology not only meets the requiring problems of various fields however likewise dramatically improves individual experience, making membrane switches over a cornerstone of modern digital design.

In the realm of modern-day electronic devices, the application of membrane layer switches is extremely considerable, spanning from streamlined consumer gadgets to important medical gadgets.Why are membrane switches over so common in consumer electronics? Membrane layer buttons are cost-effective to produce, making them an appealing choice for high-volume production normal in consumer electronic devices. From microwave ovens to remote controls, membrane layer buttons provide a functional, easy to use interface that supports the vibrant nature of customer electronic devices.